| Certificates/Standards: | N; |

| Monthly Output: | Not provided |

| Regional: | 1-1 XiShanLi QianTong Ninghai County, Ningbo 315600, Zhejiang China |

| Packaging Information: | wooden case |

| Mode Of Payment: | Not provided |

| Delivery Lead Time: | Not provided |

| Main Sales Markets: | North America,Central/South America,Western Europe,Eastern Europe,Australasia,Asia,Middle East,Africa |

| Sample Provided: | No |

| Sample Policy: | Not provided |

| Minimum Quantity: | Not provided |

Candy Bar Production Line

Automatic chocolate coated candy bar production line is the most advanced production equipment for candy bars with chocolate enrobing. All the process including kitchen system, candy bar forming and chocolate coating and decorating. It is one of the best combined production lines to enlarge the capacity and make varies kinds of bars with or without chocolate enrobing or decorating.

High-quality rollers designed to guarantee both precise forming and optimum cold transfer from the chiller to the product.

The outstanding performance of the cooling equipment and system used for subsequent drying of product layer(s).

Maximum efficiency and reliability and the option of varying cut dimensions, both in terms of length and width.

ADVANTAGES

1.Modular machine that can be adapted for production of any product the market might require: nougat or caramel layers.

2.Wide range of product sizes.

SPECIFICATION

| Capacity | 600kgs/hour (Suppose the weight of product is 10g) |

| Total power | 250KW |

| Material | SS304 |

| Most electric components | Siemens, Omron or Schneider |

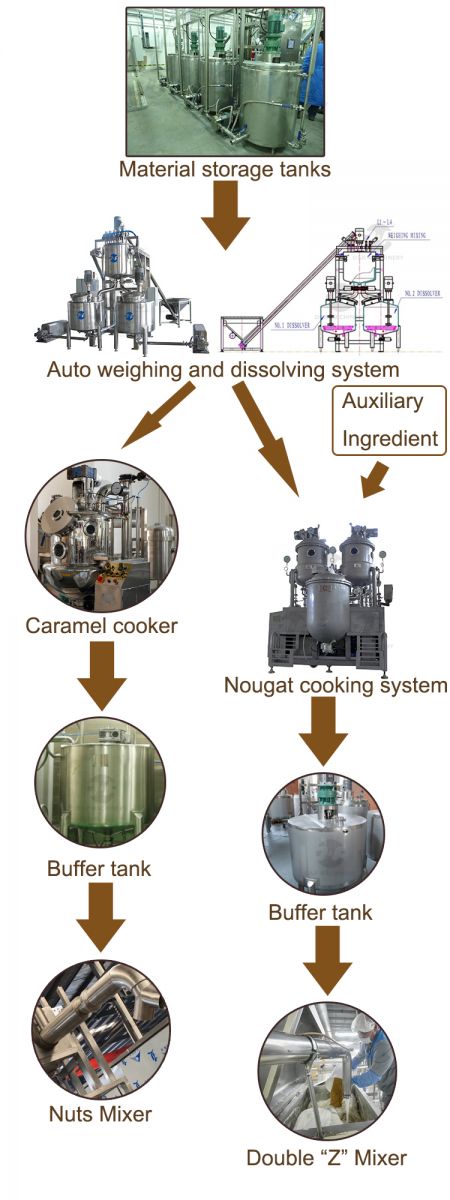

PROCESS

Kitchen system

Chocolate for enrober

Candy bar forming line

DETAILS

1.Kitchen system:

Automatic weighing and dissolving system

It includes a hopper for holding sugar, a screw to send sugar to automatic weighing and mixing tank. One automatic weighing tank on the top and two dissolving tanks below.

-Automatically→ Opration on touch screen, then syrup continuously feeding and dissolving

-Accurate→ Accurate instruments and systems to avoid manual errors

-Clean→Fully enclosed food grade stainless steel system, avoid manual contact and contaminate syrup

-Confidential→ System stores 99 recipes, with 3 levels password, workers only can select recipe to produce as schedule by using normal password; Only the boss can see the detailed recipe content by the final password

Nougat cooking system

-PLC and touch screen

-Total power:20.4kw

-SS304 steel frame. The parts which contact products are ss304

Caramel Batch Cooking System

-Production capacity: 150kg/h

-Volume: 390L

-SUS304

-Jacket max working pressure:0.6Mpa

-Air discharging system

-Dimension: 1500*950*2100mm

Double Z blades mixer

-The jacket is ss304. The base is casting iron and frame is also iron with paint.

-It is used to mix granola, nuts and syrup.

-Capacity:500L

-Active stirrer speed:33r/min

-Passive stirrer speed:22r/min

-Main motor power: 22kw

-Lift motor power: 1.5kw

-Heating power:220v 3X1.2KW=3.6kw

-Dimensions: 2600x2170x2200mm

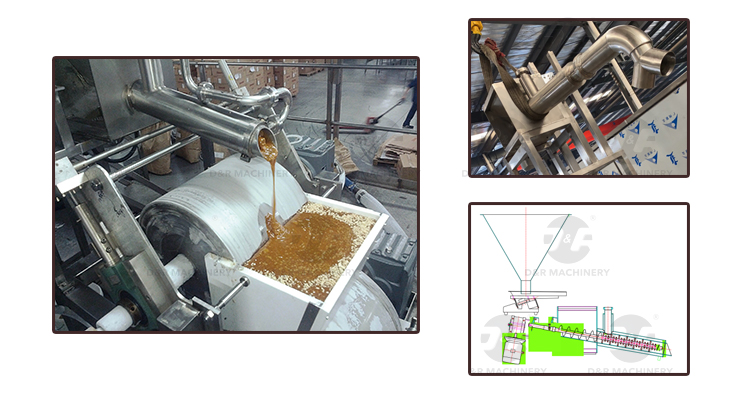

Caramel online mixer

-For mixing the caramel and nuts

-SUS304

-With viberating hopper

-Mixing speed is adjustable

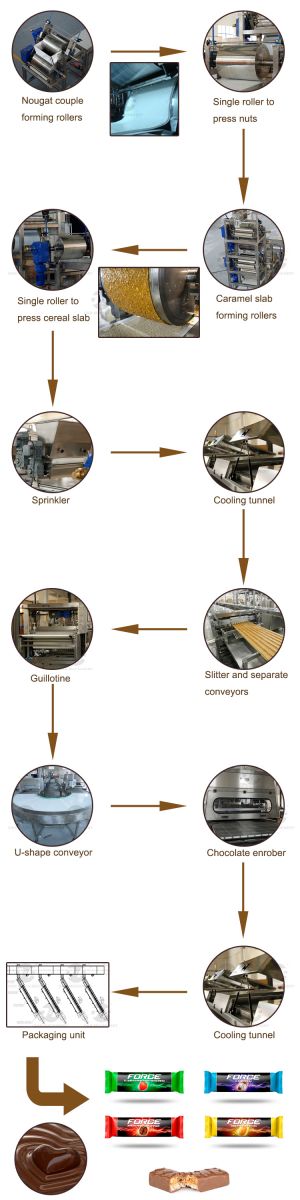

2.CANDY BAR FORMING LINE:

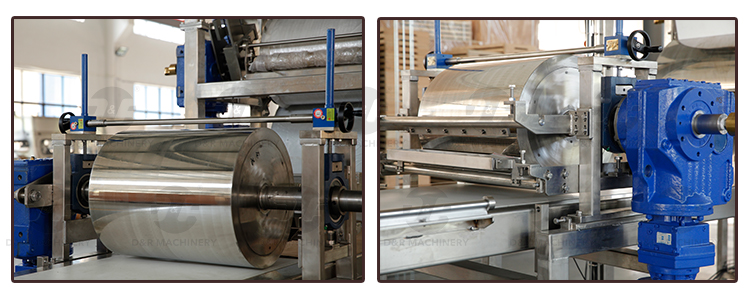

Nougat couple forming rollers

-It is for forming the nougat slab.

-The roller has cooling water in the jacket layer from brine water tank.

-The distance between two rollers can be adjusted according the thickness of products.

-The rollers,scraper,tube are ss304.

-Total power:1.5kw(two 0.75kw gear motors).

-Inverter to control, speed adjustable.

-Rollers are jacket with brine water to cool.

-Oil lubrication of rollers.

Caramel slab forming rollers:

-Double pairs of roller for forming the caramel slab.

-The roller has cooling water in the jacket layer from brine water tank.

-The distance between two rollers can be adjusted.

Single roller to press nuts or cereal slab

-The roller will press nuts slab again to make sure slab is formed well, further more, it can be pressed to reach the thickness.Power: 1.1kw.

-The plate under the roller and belt should be strong with baffles SUS304 roller, speed adjustable).

-Jacket and cooled with brine water Tool steel scraper Frame is ss304.

-The distance between the roller and belt is adjustable.

Cooling Tunnel

-Frame: SS304.

-Insulation covers: ss304 plates with 50mm foam.

-PU conveyor belt, its speed is adjustable.Width of belt is 700mm, length is 19m.

-Photo cells and cylinders to make sure belt will run straightly.

Slitter and Separate Conveyors

-Total power: 1.29kw(vertical cutter:0.37kw; separate conveyors:0.55kw and scraps recycling device:0.37kw)

-Frame is ss304

-Quantity of cutters goes on the quantity of bars.

-Cutters are tool steel.

-Speed of cutter roller is adjustable.

-A plexi glass cover to guard the safety of operator.

-There are PTFE leading bars between nuts bars.

-Quantity of separate small conveyors are same to the rows of nuts bars.Speed of belts are adjustable.

-Scraps at the two sides of nuts slab are be sent to the recycling device by belts.

Guillotine

-Total power: 1.8kw

-Frame is ss304.

-Two parts of conveyor belts, PU material, speed adjustable.

-Cylinders to make sure belts will run straightly.

-Cutter is tool steel. To set its speed manually.

-A plexiglass cover to guard the safty of operator.

Chocolate Enrober

-It can coat all sides of products or the bottom of products.

-The material of the conveyor belt is PU.

-There are PLC and touch screen to control the enrober and separate control panel for cooling tunnel.

-The frame, insulation plates and other most parts are ss304.

-The inside layer of jacket tank(hopper) under the enrober is ss304, it can be pulled out to clean.

-Under the enrober, there is a chocolate feeding pump to send chocolate mass back to chocolate storage tank.

| Model | TYJ800 | Tunnel Working Temperature | 0-10ºC |

| Mesh Belt Width | 800mm | Length of cooling tunne | 17.7m |

| Mesh Belt Speed | 0-3m/min | Power | 9.17kw |

| Conveyor Belt Width | 800mm | Weight | 2300kg |

| Convey Belt Speed | 0-3m/min | Dimension |

20150*1340*1800 |

Company Introduction

TOTAL SOLUTION ,TOTAL CARE

D&R Machinery are professional confectionery machine manufacturers with over 20 years in the business operating at the highest industry standards.

We've built a reputation on engineering, designing and delivering high performance total-solution confectionery machinery to clients with absolute precision around the world.

The confectionery machinery industry is a small world, and we've slowly become leaders in innovation and creative solutions for clients from all walks of the industry. D&R Machinery has become synonymous with one word and one world only in the confectionery machinery world and that is 'total-solution', that is end to to end turn key production of the highest quality confectionery machinery in the world.

Becoming the D&R Machinery you see today starts and ends with the word 'care'. You don't become the best without a plan that ensures our clients achieve the success they desire, and at D&R Machinery it starts with care and ends with trust, reliability and innovation.

FACTORY

WORKSHOP

EXHIBITION

CERTIFICATION

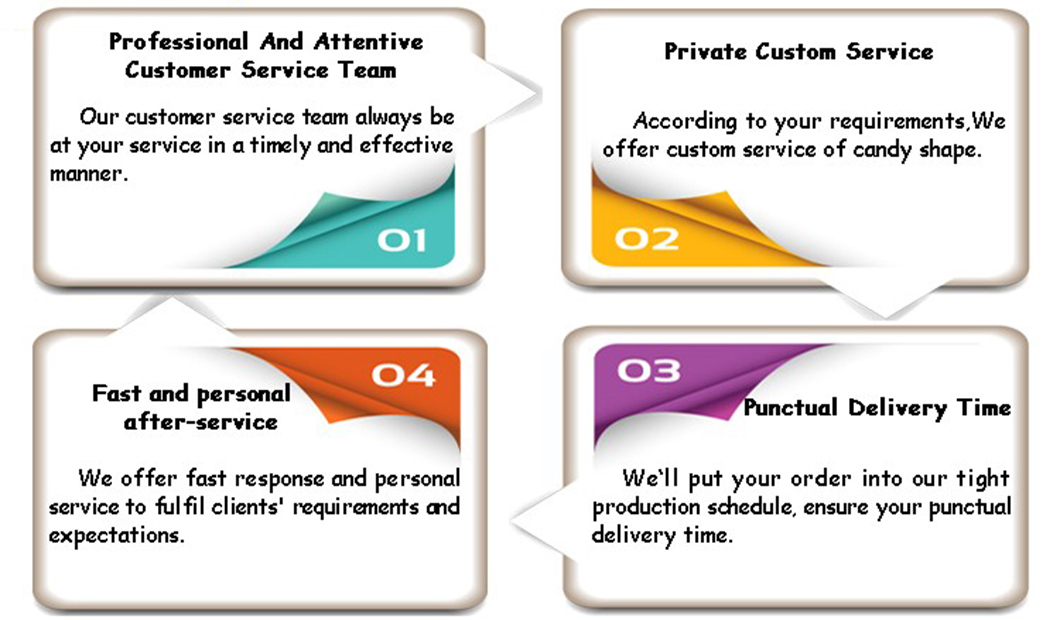

OUR SERVICE

CHIEF EXPERT

LABORATORY

PATENT

FAQ

1.Q:where are your company?

A:The company is located at room 10B09 Hualian Buliding NO.55 Dongdu Road Ningbo China.

2.Q:Are you direct factory?

A:We are both manufacturer and trading companiesno one knows more about our products than we do.We can provide the best quality equipment and the most affordable price, and according to your request, we can more quickly provide the corresponding service Scheme.Certainly,We welcome you to come visit our factory.

3.Q:What are your main products?

A:All kinds of chocolate making machines, candy making machines,Swiss roll and layer cake production line, cadny bar production line and their packing machines.

4.Q:Do you have gurantee for your product?

A:As a factory, no one knows more about our products than we do.We have a fairly strict standard for our products.Our products have CE certification and EAC certification.

5.Q:How can we contact you?

A:Here is contact information:

Contact company: Ningbo D & R Machinery Co., Ltd

Website: